HNBR3305L

Details

Product Name: HNBR3305L

Specification:

|

Grade |

ACN, % |

Mooney ML(1+4), 100°C |

Hydrogenation Degree, % |

Volatiles, %, Max |

Ash, %, Max |

Corresponding grade |

||

|

ZEON |

THERBAN |

ZHANBER |

||||||

|

RC3601 |

33±3.5 |

85±5 |

99 Min |

0.60 |

0.80 |

2000 |

3406 |

ZN35058 |

|

RC3301L |

33±2 |

60±10 |

99 Min |

0.60 |

0.80 |

- |

- |

- |

|

RC3605 |

33±3.5 |

85±5 |

95±2 |

0.60 |

0.80 |

2010 |

3629; 3467 |

ZN35158 |

|

RC3605D |

36±3.5 |

80±5 |

95±2 |

0.60 |

0.80 |

- |

3668 |

- |

|

RC3305L |

33±3.5 |

60±5 |

95±2 |

0.60 |

0.80 |

2010L |

3446 |

ZN35156 |

|

RC3603 |

35.5±2 |

90±5 |

95±2 |

0.60 |

0.80 |

- |

- |

- |

|

RC3303 |

33±3.5 |

85±5 |

95±2 |

0.60 |

0.80 |

- |

- |

- |

|

RC3310L |

33±3.5 |

60±5 |

91±2 |

0.60 |

0.80 |

2020L |

- |

ZN35256 |

Introduction of HNBR: Hydrogenated butadiene-acrylonitrile rubber (HNBR) is a highly saturated elastomer which is

treated by catalytic hydrogenation of nitrile rubber (NBR). Compared with NBR, the molecular structure of HNBR contains

a small amount or no carbon-carbon double bonds. The HNBR has better thermal oxygen aging, ozone resistance,

radiation resistance, chemical medium resistance (acid, alkali, methane, refrigerant, hydrogen sulfide) and good dynamic

properties than NBR, while maintaining the oil resistance and wear resistance of NBR. The HNBR is a special rubber with

excellent comprehensive properties, which is a national strategic material.

Application: HNBR is widely used in aerospace, automotive industry, oil drilling, machinery manufacturing, textile &

printing and other fields. It is mainly used in automobile fuel system components, auto transmission belts, drilling

confinements, packer rubber tubes of oil wells, submersible pump cable sheaths of ultra-deep wells, bops, directional

drillings, stator motor matching hoses of offshore oil drilling platforms, seals of aeronautics and astronautics, tank track

pads, foam cushioning materials, seals of nuclear industry, hydraulic pipes, air conditioning seal products, textile &

printing rubber rollers, etc.

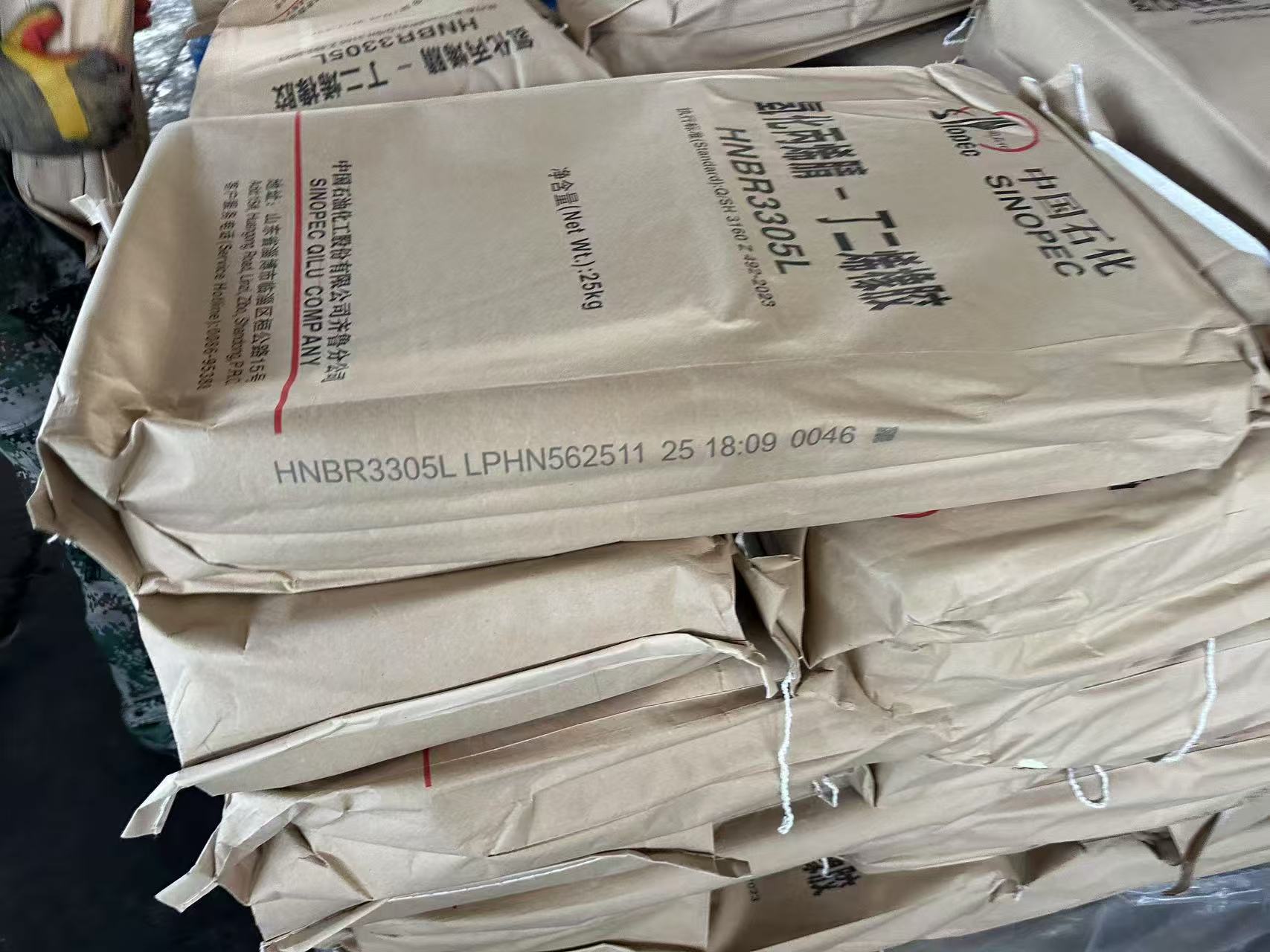

Packing: In 25kgs bag.

Storage: Keep container tightly closed in a cool, dry and well-ventilated place, avoiding exposure of the packaged product to direct sunlight.

Send Us a Message

How can we help you ? Get in touch!